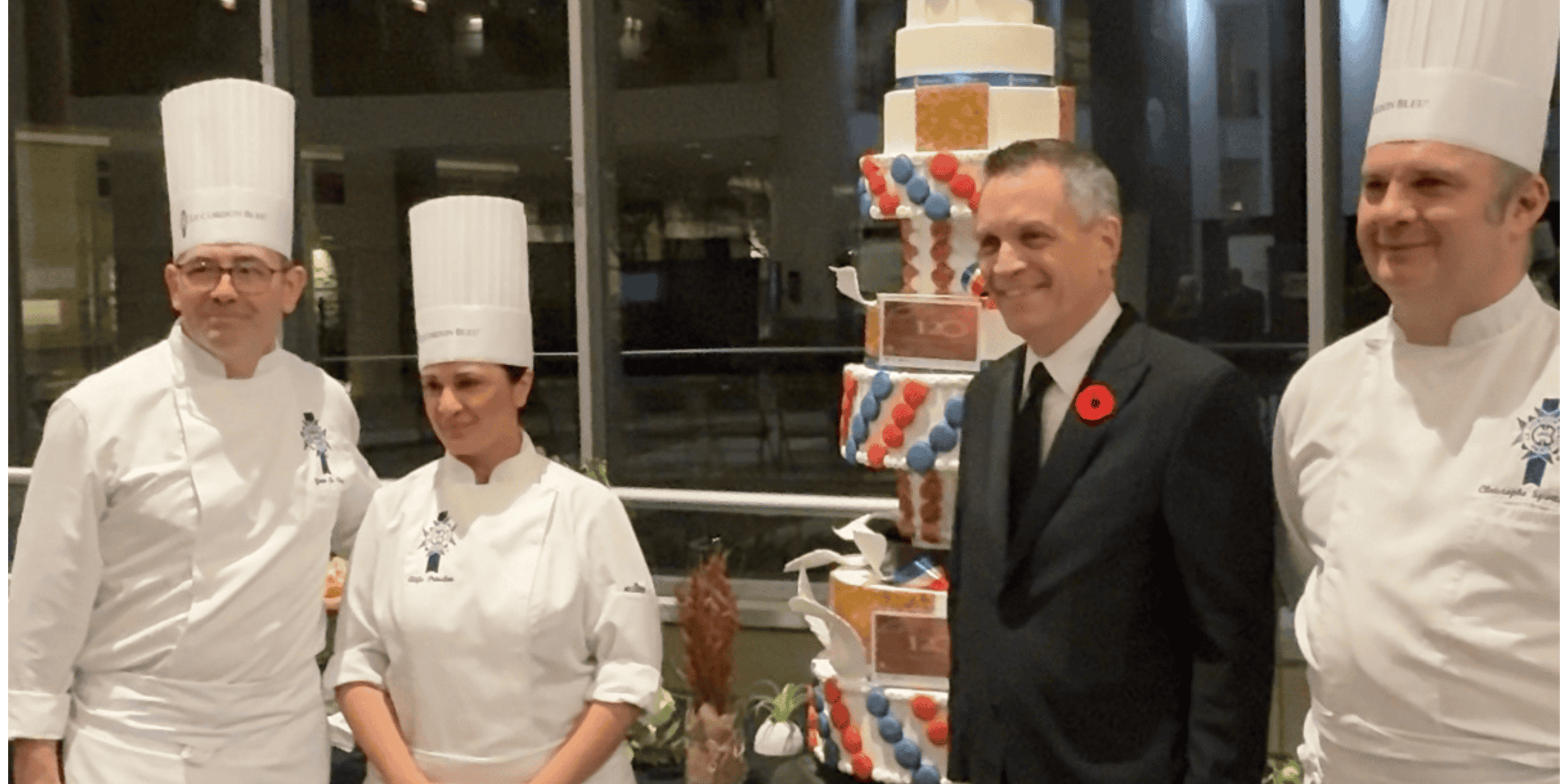

Le Cordon Bleu Ottawa Celebrates 120 Years of Alliance Française Ottawa

Le Cordon Bleu Ottawa Celebrates 120 Years of Alliance Française Ottawa

In February 2016, Le Cordon Bleu hosted in collaboration with Gekkeikan, a long-standing Japanese sake producer, the very first sake brewery excursion in Fushimi, Kyoto. Mototsune Aikawa, the chief brewer at Gekkeikan and Sebastien Lemoine were the lecturers and I'll share what we learned.

Our group visited Gekkeikan Okura Sake Museum in Kyoto on a bright but bitterly cold winter day. The area was littered with sake storehouses, streaked with white earth, and mortar walls ran along the Horikawa River that used to be the outer moat of Fushimi Castle. Gekkeikan Okura Sake Museum conveys the history of sake brewing in Fushimi and Gekkeikan Sake Company. It's situated in the heart of Fushimi and the building itself, renovated in the Meiji period, used to be a sake brewery.

Today, they still brew sake in the Uchigura brewery that faces the courtyard of the museum, and they continue to use traditional methods to do it. The aroma of sake wafts through the area during the peak brewing season for kanzukuri (winter-brewed refined sake). We spent two days at Uchigura brewery, participating in the actual brewing of the winter sake, and it's not called kanzukuri for nothing: the entire brewing process is done in hand-numbingly frigid conditions.

A typical day at the brewery starts in the morning with paying respects to a household Shinto altar. Then the first step is to wash several kilos of rice, and soak it in water. Rice absorbs water quickly so they have to constantly attend to it. The washed rice then gets in the steaming vat, which fills the entire brewery with the aroma of steamed rice. Next, koji (molded rice made from Aspergillus oryzae) is mixed with Fushimi's ground water to make moromi, the main fermenting mash.

This process is carefully monitored by touch and sight and brewing normally takes four days. We arrived on the third day of the process where the moromi was already prepared and was beginning to ferment and bubble. Fushimi's ground water, koji, and the rice are then combined in the wooden sake container for fermentation and mixed with a kai, a paddle for stirring. By the fourth day, the mixture stiffens and it gets harder to use the kai. In sake brewing, all tools need to be boiled and sterilized immediately after use in order to prevent bacteria growth. For that reason, clean-up is taken very seriously. Countless sheets of cloth – used to strain and squeeze rice – hung to dry after washing is a common sight in breweries.

After our two days at Uchigura brewery, we went to Ootegura brewery. There, the same processed was used, but it was done using machines. Whether the sake brewing is mechanized or done manually, the process is the same, keeping the spirit of chief brewer and skilled brewers alive. Our understanding of the world of sake was deepened thanks to the lectures that taught us sake tasting and the history of prominent breweries.

The day ended with a food and sake pairing session. La Famille Morinaga (French restaurant)and Rantei (Japanese restaurant) prepared cuisine that was paired with five different kinds of sake presented by Gekkeikan. We all ate with great gusto listening to the chefs, licensed sake tester and sommelier. Mr. Aikawa, the chief brewer, shared his thoughts on how they go about selecting the right sake for pairing. Perhaps the best take-away (literally) from this educational excursion is the sake we had a hand in brewing. It'll be ready soon and I'm very excited to have a sip of my own brew.

Copyright © 2026 Le Cordon Bleu International B.V. All Rights Reserved.